Tem dúvidas sobre a origem das suas pás? Esta incerteza pode afetar o seu negócio e o que diz aos seus clientes. Dar-lhe-ei uma história clara e interna sobre o fabrico da Selkirk.

Pás de qualidade superior da Selkirk1 (Selkirk, Selkirk LABS) são fabricados e acabados à mão em Hayden, Idaho, EUA. A sua linha económica SLK by Selkirk é produzida na China sob rigorosos padrões de design e qualidade Selkirk. Esta estratégia de duplo fornecimento é a chave para o seu domínio do mercado.

Principais parceiros comerciais na China:

- DONGGUAN SHANGZE SPORTING GOODS CO

- CHINA RAINBOW INTERNATIONAL INDUSTR

- ARTIGOS DESPORTIVOS DE YANGZHOU KAIWEI

- ZHANGZHOU ZEUS COMPOSITE TECH

- UNIKER SPORT CO LTD

- YANGZHOU SUNNY INTERNATIONAL

- XIAMENJUQIAO COMPOSITE TECH CO.,LTD

Quando comecei a trabalhar numa fábrica de pás, a primeira coisa que aprendi foi que "onde" uma pá é feita conta uma história. Diz-nos quais são as prioridades da marca, as suas controlo de qualidade2e a sua estratégia comercial. Para qualquer pessoa no sector do pickleball, desde proprietários de marcas como Maggie e Grace at Recess a grandes distribuidores, compreender esta história não é apenas interessante - é essencial. Ajuda-o a escolher os produtos certos, a gerir o seu inventário e a explicar o valor aos seus clientes. A história da Selkirk é uma das mais interessantes da indústria e é um estudo de caso perfeito para equilibrar a produção doméstica de alta qualidade com a produção global acessível. Vamos explicar.

Todas as pás Selkirk, incluindo a linha SLK, são fabricadas nos EUA.Falso

Apenas as pás premium Selkirk e Selkirk LABS são fabricadas nos EUA. A linha SLK by Selkirk é fabricada na China para tornar o desporto mais acessível a um preço mais baixo.

Os remos "Made in USA" da Selkirk são fabricados em Hayden, Idaho.Verdadeiro

A sede da Selkirk Sport e as principais instalações de fabrico das suas pás de alto desempenho estão localizadas em Hayden, Idaho.

Onde exatamente são feitas as pás Selkirk? Na fábrica de Hayden, Idaho?

Ouve-se dizer "Made in USA", mas o que é que isso significa realmente para um remo? Sem conhecer os pormenores da operação, não é possível avaliar verdadeiramente a qualidade ou a história.

As pás de alto desempenho da Selkirk, incluindo as populares VANGUARD, AMPED e os inovadores projectos LABS, são fabricadas e meticulosamente acabadas à mão na sua fábrica dedicada em Hayden, Idaho. Estas instalações são o coração da sua marca, impulsionando a investigação, o desenvolvimento e o controlo de qualidade dos seus produtos de qualidade superior.

Ter uma fábrica doméstica em Hayden, Idaho, é uma enorme vantagem estratégica para a Selkirk. Já trabalhei com dezenas de fábricas e posso dizer que ter a sua equipa de I&D a apenas alguns passos da linha de produção é um fator de mudança. A Selkirk diz que cria centenas de protótipos para cada novo modelo. Esta iteração rápida só é possível com uma instalação interna. Permite-lhes testar novos materiais, como a fibra de carbono Florek™, e aperfeiçoar técnicas de termoformagem3 em tempo real.

Esta supervisão rigorosa também os ajuda a cumprir os regulamentos da USA Pickleball mais rapidamente do que os concorrentes que dependem da produção no estrangeiro. Mas, para mim, a parte mais importante é a forma como apoia a sua garantia vitalícia4. A gestão de devoluções, reparações e substituições é muito mais eficiente quando a fábrica se encontra no mesmo país. Cria uma confiança incrível na marca, que é algo que todos os empresários com quem trabalho procuram alcançar. O processo de acabamento manual em Idaho não é apenas para exibição; é uma verificação de qualidade final e crítica que garante que cada raquete de qualidade superior cumpre os seus padrões exigentes.

A fábrica da Selkirk em Idaho só monta pás a partir de peças fabricadas na China.Falso

A fábrica de Idaho trata dos principais processos de fabrico, incluindo a colocação de materiais compósitos, a prensagem e o acabamento das suas linhas premium. É muito mais do que uma simples montagem.

A produção nacional permite à Selkirk desenvolver e testar centenas de protótipos para cada modelo de pá.Verdadeiro

Ter I&D e fabrico no mesmo local permite um processo de design rápido e iterativo, o que é uma vantagem fundamental das suas instalações em Hayden, Idaho.

Fabricado nos EUA vs. Montado nos EUA: O que significa realmente o rótulo da Selkirk?

A etiqueta "Made in USA" pode ser confusa, e os pormenores são importantes. Uma má interpretação pode levá-lo a fazer escolhas erradas em termos de inventário ou a informar mal os seus clientes sobre o valor de um produto.

Para a Selkirk, "Made in the USA" significa que os principais processos de fabrico - desde a colocação de materiais compostos em bruto até à prensagem, montagem final e acabamento manual - ocorrem em Idaho. Esta é uma afirmação muito mais forte do que "Montado nos EUA", que muitas vezes significa apenas juntar peças importadas pré-fabricadas.

Esta distinção é fundamental, especialmente no mercado das pás de alto rendimento. Quando se está a lidar com materiais avançados5 Como as faces de fibra de carbono termoformadas, o controlo de qualidade interno não é negociável. Eu vi em primeira mão como pequenas variações de calor, pressão ou consistência do material podem arruinar um lote de pás. Ao controlar todo o processo em Idaho, a Selkirk pode garantir um nível de consistência que é difícil de alcançar à distância. É por isso que os jogadores focados no desempenho e os retalhistas conhecedores sabem que o prémio de preço 10-15% para uma raquete nacional é muitas vezes justificado.

Do ponto de vista da logística empresarial, os benefícios são igualmente claros. Os dados internos da Selkirk mostram que o acabamento manual em Idaho reduz o tempo de espera para o seu armazém em cerca de 18-25 dias, em comparação com a importação de produtos acabados através dos portos da Costa Oeste. Para qualquer retalhista ou distribuidor, reduzir três a quatro semanas do tempo de entrega é uma grande vitória para gestão do inventário6 e fluxo de caixa. Isto significa que pode reagir mais rapidamente às tendências do mercado e evitar rupturas de stock. Esta eficiência operacional é uma vantagem oculta do modelo "Made in USA" que ajuda diretamente os seus parceiros comerciais.

As etiquetas "Made in USA" e "Assembled in USA" significam a mesma coisa.Falso

A FTC tem diretrizes rigorosas. "Fabricado nos EUA" significa que "todo ou praticamente todo" o produto é fabricado no país, enquanto "Montado nos EUA" pode aplicar-se a produtos fabricados com componentes estrangeiros significativos.

O fabrico nacional proporciona à Selkirk um melhor controlo da qualidade dos materiais compósitos avançados.Verdadeiro

A produção interna permite controlos de qualidade imediatos em processos complexos como a termoformagem, que é crucial para o desempenho e a durabilidade das pás de alta qualidade.

SLK da Selkirk: Porque é que a linha Budget é fabricada na China?

Vê-se o nome de confiança Selkirk num remo muito mais barato. Será que é a mesma qualidade? Esta confusão de marcas pode dificultar o posicionamento dos produtos e pode prejudicar as vendas se não for explicada corretamente.

A linha SLK by Selkirk é intencionalmente fabricada na China para tornar o pickleball mais acessível. Esta estratégia permite à Selkirk oferecer qualidade, pás de nível básico a um preço mais baixo, utilizando a escala de fabrico da China, enquanto continua a aplicar os seus próprios princípios de design e engenharia comprovados.

Esta é uma estratégia de marca clássica e muito inteligente, com dois níveis. Estou sempre a ajudar os meus clientes a desenvolver abordagens semelhantes. Protege-se a perceção de qualidade da marca principal (Selkirk) enquanto se capta um segmento de mercado completamente diferente (principiantes, jogadores casuais) com uma submarca (SLK). Para o efeito, a Selkirk estabelece parcerias com fabricantes chineses estabelecidos. Com base nos registos públicos de importação, os seus parceiros incluem empresas como a DONGGUAN SHANGZE SPORTING GOODS CO e a ZHANGZHOU ZEUS COMPOSITE TECH. Não se trata de pequenas oficinas; são fábricas grandes e capazes de produzir grandes volumes de forma eficiente.

O compromisso é claro e é importante ser transparente com os clientes. Obtém-se um preço mais baixo, mas também se obtém uma garantia mais curta e um produto construído para ser acessível, não para ter um desempenho de ponta. Os dados contam a história toda.

Selkirk vs. SLK: Uma comparação clara

| Métrica | Premium Selkirk / LABS | SLK por Selkirk | Média do sector |

|---|---|---|---|

| Localização da produção | Hayden, Idaho, Estados Unidos | Guangdong, China | 62% China, 20% Taiwan, 18% EUA |

| Duração da garantia | Vida útil | 1 ano | 1-2 anos |

| Preço médio. Preço de retalho (2025) | $199-$333 | $69-$129 | $110 |

| Taxa de Retorno/Defeito (2024) | 2.7% | 8.5% | 7.2% |

| Tempo médio Tempo de espera até ao armazém nos EUA | 5 dias | 25 dias (marítimo/ferroviário) | 18 dias |

(Fontes: Livro branco sobre logística interna da Selkirk, 2025; Verified Market Research, 2025)

Como se pode ver, a taxa de defeitos e os prazos de entrega da linha SLK são mais elevados, o que é típico dos produtos importados. No entanto, permite à Selkirk competir a um nível de preços que não poderia atingir com o fabrico nos EUA, trazendo novos intervenientes para o ecossistema da Selkirk.

As pás SLK são fabricadas na mesma fábrica de Idaho que as pás Selkirk de qualidade superior.Falso

As pás SLK são produzidas por parceiros de fabrico na China, como a DONGGUAN SHANGZE SPORTING GOODS CO, para conseguir um preço mais baixo.

A linha SLK tem uma garantia mais curta e uma taxa de defeitos mais elevada do que a linha premium Selkirk.Verdadeiro

Os dados mostram que a linha SLK tem uma garantia de 1 ano e uma taxa de defeito de 8,5%, em comparação com a garantia vitalícia e a taxa de defeito de 2,7% das pás premium fabricadas nos EUA.

Visita prática: Como é que uma raquete Selkirk passa das folhas de carbono para o campo?

Um remo é apenas um remo, certo? Se pensa assim, não consegue explicar o valor real aos seus clientes. Compreender o processo é fundamental para comunicar a qualidade e justificar o preço.

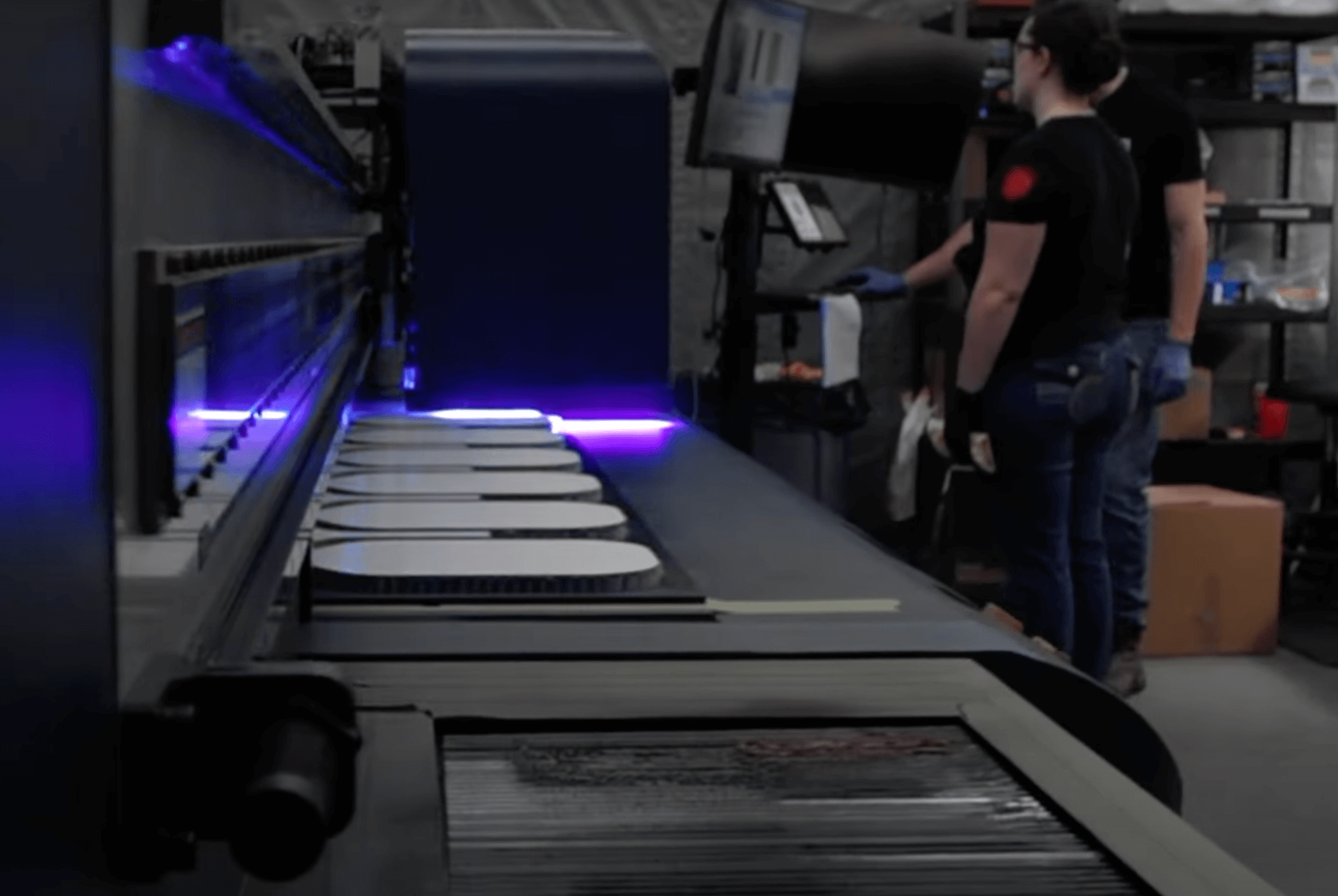

Uma raquete Selkirk premium começa como folhas brutas de fibra de carbono na sua fábrica em Idaho. Passa por cortes precisos, camadas, prensagem a quente (termoformação), inserção de núcleo, aplicação de proteção de borda e acabamento manual detalhado antes de ser aprovada para o campo.

Tendo passado anos no chão de fábrica, adoro ver como as coisas são feitas. O processo para uma raquete Selkirk de alta qualidade é uma mistura de tecnologia e habilidade.

Etapa 1: Corte e disposição do material

Tudo começa com matérias-primas, principalmente fibra de carbono de alta qualidade. Estas folhas são cortadas em padrões precisos. De seguida, os trabalhadores colocam cuidadosamente as folhas em camadas, muitas vezes em orientações específicas, para obter a rigidez e o toque desejados. Esta fase de colocação é crítica e é um fator importante no desempenho de uma pá.

Etapa 2: Termoformagem e prensagem

Os materiais em camadas, juntamente com o núcleo alveolar de polipropileno, são colocados num molde. O molde é aquecido e submetido a uma enorme pressão. Este processo, conhecido como termoformação, une todas as camadas, criando um corpo de pá único e sólido. É aqui que a Selkirk cria a sua construção unibody, que aumenta a durabilidade.

Etapa 3: Acabamento e montagem

Quando a pá sai da prensa, o trabalho está longe de estar terminado. É aqui que o acabamento manual em Idaho realmente brilha. Os rebordos são lixados, a proteção dos rebordos é meticulosamente aplicada e o punho é construído e revestido com uma pega. Cada passo é efectuado por um técnico qualificado.

Etapa 4: Controlo de qualidade

Por fim, cada pá é submetida a um controlo de qualidade rigoroso. São pesadas, testadas na balança e inspeccionadas visualmente para detetar quaisquer defeitos estéticos. Apenas as pás perfeitas recebem a aprovação final. Este processo prático e de várias fases é o que está a pagar por uma raquete de qualidade superior, fabricada nos EUA.

As pás de qualidade superior da Selkirk são produzidas em massa por máquinas, sem supervisão humana.Falso

Embora sejam utilizadas máquinas para processos como a prensagem, as pás são submetidas a um acabamento manual significativo, montagem e controlo de qualidade por técnicos especializados em Idaho.

A termoformagem é um processo fundamental em que o calor e a pressão são utilizados para unir as camadas da palheta.Verdadeiro

Este passo de fabrico é crucial para criar uma raquete durável e de alto desempenho e é o foco da produção interna da Selkirk.

Conclusão

A Selkirk utiliza uma estratégia inteligente de fabrico duplo: as pás premium são fabricadas nos EUA para desempenho e qualidade, enquanto as pás SLK são fabricadas na China para acessibilidade e crescimento.

Referências

-

Explore as qualidades e vantagens únicas das pás premium da Selkirk, fabricadas nos EUA. ↩

-

Descubra como um rigoroso controlo de qualidade garante o desempenho e a durabilidade das pás. ↩

-

Explore as técnicas inovadoras de termoformagem que melhoram o desempenho das pás. ↩

-

Saiba mais sobre o significado de uma garantia vitalícia e o seu impacto na confiança do cliente. ↩

-

Explore os materiais avançados que contribuem para o elevado desempenho das pás Selkirk. ↩

-

Compreender a relação entre a localização do fabrico e a gestão eficaz do inventário. ↩