ترى اسم JOOLA وتفكر في الهندسة الألمانية. ولكن بعد ذلك ترى الصندوق. هذا يخلق ارتباكاً لك ولعملائك، وقد يكون من الصعب شرحه.

صُممت مجاذيف كرة المخلل من JOOLA في ألمانيا وماريلاند بالولايات المتحدة الأمريكية، ولكن يتم تصنيعها في مصانع ألياف الكربون1 في الصين. يتم شحنها بعد ذلك إلى JOOLA أمريكا الشمالية لفحص الجودة النهائية وتوزيعها على تجار التجزئة مثلك.

قد يفاجئ هذا الأمر بعض الأشخاص، ولكن بصفتي شخصًا قضى سنوات داخل مصانع كرة المخلل وبناء سلاسل التوريد، يمكنني أن أخبرك أن هذا مثال مثالي لتصنيع السلع الرياضية الحديثة. إنها قصة يجب أن يفهمها كل مالك علامة تجارية وتاجر تجزئة وموزع لكرة المخلل. إن "السبب" وراء هذه الخطوة هو درس قوي في كيفية بناء علامة تجارية عالمية ناجحة اليوم. دعنا نوضح كيف يتم ذلك وما الذي يعنيه ذلك بالنسبة لعملك.

لا تزال جميع مجاذيف كرة المخلل من JOOLA مصنعة في مصنعها الألماني الأصلي.خطأ

هذا مفهوم خاطئ شائع. فبينما تأسست JOOLA في ألمانيا ولا تزال تقوم بأعمال البحث والتطوير هناك، فإن جميع مجاذيف كرة المخلل التجارية الخاصة بها يتم إنتاجها الآن بكميات كبيرة في الصين.

يتم تصميم مجداف JOOLA وهندسته في كل من ألمانيا والولايات المتحدة.صحيح

تحتفظ شركة JOOLA بجذورها الهندسية في لانداو بألمانيا، ولديها مختبر رئيسي للبحث والتطوير في مقرها الرئيسي في أمريكا الشمالية في روكفيل بولاية ماريلاند.

من الجذور الألمانية إلى الإنتاج الصيني: كيف تطورت سلسلة التوريد الخاصة بشركة جوولا؟

أنت تريد بناء علامة تجارية ذات تراث قوي، ولكنك تحتاج أيضًا إلى التعامل مع تكاليف الإنتاج الحديثة. إنه توازن صعب. واجهت JOOLA هذه المشكلة بالضبط.

قامت جولا، العلامة التجارية الألمانية التي تأسست عام 1952، بتحويل استراتيجيتها إنتاج مضرب كرة المخلل2 إلى الصين. وتسمح لهم هذه الخطوة بالاستفادة من سلاسل التوريد الأكثر تقدماً في العالم من ألياف الكربون، وخفض تكاليف الإنتاج بشكل كبير، والعمل بالقرب من كبار المصنعين الآخرين لتسهيل اختبار الامتثال.

حكاية قارتين

تبدأ قصة جوولا في لاندو بألمانيا، حيث بنت الشركة سمعة طيبة في مجال معدات تنس الطاولة ذات المستوى العالمي. ولعقود من الزمن، كانت عبارة "صُنع في ألمانيا" هي السمة المميزة لها. في أيامي الأولى في هذه الصناعة، رأيت كيف كانت هذه العلامة تحمل ثقلًا كبيرًا. لكن طفرة كرة الطاولة غيرت اللعبة. فالطلب على المواد المتقدمة، وتحديدًا ألياف الكربون3نمت بسرعة مذهلة.

وقد قاد ذلك شركة JOOLA إلى اتخاذ قرار استراتيجي. ففي حين أنها لا تزال تطحن بعض شفرات تنس الطاولة ذات الدفعات المحدودة في ألمانيا، إلا أنها نقلت جميع عمليات إنتاج كرة الطاولة على نطاق واسع إلى مراكز ألياف الكربون في جنوب الصين، حول مدن مثل شنتشن وشيامن. لقد زرت هذه المنشآت بنفسي، ومستوى التخصص مذهل. فهي ليست مجرد مصانع عامة، بل هي مصانع عالية الدقة تخدم العديد من أفضل العلامات التجارية للمجاديف في العالم. وكانت هذه الخطوة مدفوعة بثلاثة عوامل رئيسية يجب على أي علامة تجارية متنامية دراستها:

- العمق سلسلة التوريد4: تمتلك الصين نظاماً بيئياً لا مثيل له لإنتاج ألياف الكربون، بدءاً من توريد المواد الخام إلى تقنيات التشكيل المتقدمة.

- انخفاض تكلفة الوحدة: ينتج عن التصنيع هناك تكلفة أقل 30-40% على المجاذيف الاحترافية.

- الامتثال المبسط: إن التواجد بالقرب من المصانع التي تصنع المجاذيف المنافسة يسهّل عملية اختبار الامتثال لاتحاد الولايات المتحدة الأمريكية للمجاديف.

نقلت JOOLA إنتاج كرة المخلل إلى الصين فقط لاستخدام عمالة أرخص.خطأ

وفي حين أن التوفير في التكاليف يعد أحد العوامل، إلا أن الدافع الرئيسي كان الوصول إلى النظام الإيكولوجي الصيني المتخصص والناضج للغاية لتصنيع ألياف الكربون في الصين، والذي يصعب تكراره في أي مكان آخر.

لا تزال بعض معدات تنس الطاولة المتخصصة من JOOLA تُصنع في ألمانيا.صحيح

يستمر مصنع جوولا الألماني في لانداو في إنتاج عدد قليل من شفرات تنس الطاولة المتخصصة والراقية، ولكن لا توجد مجاذيف تجارية لكرة الطاولة.

هل يؤثر بلد المنشأ على الدوران والبوب والمتانة؟

يرى عملاؤك عبارة "صُنع في الصين" فيشعرون بالقلق من أن ذلك يعني جودة أقل. هذا الشك الوحيد يمكن أن يوقف عملية البيع حتى قبل أن تبدأ. أنا هنا لأريك البيانات التي تثبت أن الأداء لا يتعلق بالجغرافيا.

لا. لا تُظهر الاختبارات المعملية المستقلة عدم وجود فجوة كبيرة في الأداء بين مجاذيف JOOLA الصينية الصنع من الدرجة الأولى ومنافسيها من الولايات المتحدة. الجودة هي نتيجة لمواد معينة، وهندسة ومراقبة العمليات، وليس موقع المصنع. وعادةً ما ترتبط مشاكل المتانة، عندما تحدث، بأساليب التصنيع مثل التشكيل الحراري، وليس البلد نفسه.

الجودة عملية وليست مكاناً

من الأسئلة الشائعة التي أتلقاها من مالكي العلامات التجارية الجديدة هو ما إذا كان التصنيع في الخارج سيضر بأداء مجدافهم أو شرعيته. الإجابة بسيطة: كرة مضرب الولايات المتحدة الأمريكية5 لا تهتم بمكان صنع المضرب. تعتمد موافقتهم على اجتياز مجموعة صارمة من الاختبارات الصارمة لأشياء مثل خشونة السطح (للدوران)، وانحراف القلب (للفرقعة)، والأبعاد. يجب على المضرب المصنوع في الصين أو الولايات المتحدة أو المكسيك أن يجتاز نفس الاختبارات بالضبط لكي يكون قانونيًا للبطولات.

من واقع خبرتي في المصنع، فإن الأشياء التي تؤثر حقاً على الجودة هي

- درجة ألياف الكربون: هل هو T700 أم T300 أم شيء آخر؟

- عملية الراتنج والتركيب: كيف يتم ربط صفائح ألياف الكربون معاً؟

- المادة الأساسية: ما نوع قرص العسل المصنوع من البولي بروبلين المستخدم؟

- تقنية التصنيع: هل هو قالب ضغط قياسي أم تصميم أكثر تعقيدًا مُشكَّل حراريًا ومحقون بالرغوة؟

تؤكد اختبارات الصلابة والحصى المستقلة ذلك. فهي تُظهر أن مضرب JOOLA الصيني جيد الصنع يؤدي نفس أداء مضرب منافس أمريكي بسعر مماثل. عندما يبلغ اللاعبون عن مشاكل مثل التفكك أو النوى المسحوقة، فغالبًا ما يعود ذلك إلى خطوط غراء التشكيل الحراري المحددة أو مشاكل في سحق النوى أثناء الإنتاج - وهي مشاكل يمكن أن تحدث في أي مصنع، في أي مكان، إذا كان مراقبة الجودة6 ليست صارمة بما فيه الكفاية

يحدد بلد منشأ المضرب ما إذا كان يمكن اعتماده من قبل الولايات المتحدة الأمريكية لكرة المضرب.خطأ

تستند موافقة الولايات المتحدة الأمريكية على كرة المضرب الأمريكية بالكامل على اختبارات المعدات الموضوعية لعوامل مثل الخشونة والانحراف. ليس لبلد التصنيع أي تأثير على هذه العملية.

غالباً ما ترتبط مشكلات المتانة في المجاذيف الحديثة بعملية التشكيل الحراري.صحيح

تنبع العديد من مشاكل المتانة المبلغ عنها، مثل التفكك أو التفكك من المواد اللاصقة والضغوط العالية المستخدمة في التشكيل الحراري، وهي تقنية تستخدمها العديد من العلامات التجارية بغض النظر عن موقع تصنيعها.

كيف يحلق التصنيع الصيني $60 من مجداف الكربون؟

تحتاج إلى تسعير مجاذيفك للمنافسة، ولكن لا يمكنك التضحية بالجودة. يبدو الأمر وكأنه خيار مستحيل. سأقوم بتحليل التكاليف الواقعية لأوضح لك كيف يتم ذلك بالضبط.

يمكن أن يؤدي التصنيع في الصين إلى خفض تكلفة الوحدة لمجداف الكربون الاحترافي بمقدار 30-401 تيرابايت 3 تيرابايت. ويأتي هذا التوفير الهائل من مزيج من وفورات الحجم، وسلسلة توريد المواد الخام عالية الكفاءة، وانخفاض التكاليف العامة مقارنة بالتصنيع في الولايات المتحدة أو أوروبا.

| متري | 2023 | 2024 | التغير السنوي | المصدر |

|---|---|---|---|---|

| إيرادات معدات كرة المضرب العالمية | $2.2 B | $3.0.0 B | +36 % | تقرير Market.US 2025 |

| المشاركون في كرة المخلل الأمريكية | 13.6 M | 19.8 M | +46 % | تقرير SFIA 2024 |

| متوسط التكلفة الإجمالية لاستيراد مجداف من ألياف الكربون من SZ إلى مطار لوس أنجلوس الدولي (40 بوصة من المقر الرئيسي، مدفوعة الرسوم الجمركية) | $38 | $41 | +8 % | مؤشر فريتوس الموضعي، عينة داخلية |

الأرقام الكامنة وراء الاستراتيجية

لننظر إلى الجدول أعلاه. تُظهر البيانات أن متوسط تكلفة إنتاج مجداف من ألياف الكربون المتطورة في أحد المصانع الكبرى في شنتشن وشحنه إلى لوس أنجلوس يبلغ حوالي $41. والآن، ضع في اعتبارك أن مجدافًا مماثلًا مصنوعًا في الولايات المتحدة يمكن أن تبلغ تكلفة الوحدة $100 أو أكثر. هذا الفرق $60 هو فرق يغيّر قواعد اللعبة. لا يتعلق الأمر بالربح فقط. هذا الهامش الإضافي هو ما يسمح لعلامة تجارية مثل JOOLA بالتعاقد مع لاعب #1 في العالم، بن جونز، وتمويل البحث والتطوير7 يحدث في مختبرهم في ماريلاند.

ولهذا السبب ترى ملصقات مكتوب عليها "صُمم في الولايات المتحدة الأمريكية وصُنع في الصين" على علب المجاديف. إنها ليست خدعة؛ إنها انعكاس لاستراتيجية عالمية ذكية. يحدث الابتكار والتصميم الأساسي في المقر الرئيسي لشركة JOOLA في الولايات المتحدة، لذا يسمح قانون الجمارك بوضع هذه الملصقات. بالنسبة لعلامة تجارية مثل Recess Pickleball، التي أسستها ماجي وغريس، فإن فهم هيكل التكلفة هذا أمر حيوي. فهو يسمح لهم بابتكار مجاذيفهم النابضة بالحياة والمرح بسعر لا يزال في متناول الجميع، دون المساومة على الجودة التي يتوقعها عملاؤهم.

ظلت تكلفة استيراد مجداف من ألياف الكربون من الصين ثابتة.خطأ

ووفقًا لبيانات Freightos، ارتفع متوسط التكلفة الإجمالية لاستيراد مجداف من شنتشن إلى لوس أنجلوس بمقدار 81 تيرابايت 3 تيرابايت 3 تيرابايت من عام 2023 إلى 2024، حيث ارتفع من 1 تيرابايت 4 تيرابايت 38 إلى 1 تيرابايت 4 تيرابايت 41.

زاد عدد لاعبي كرة المخلل في الولايات المتحدة بما يقرب من 501 تيرابايت في عام واحد.صحيح

ذكرت جمعية صناعة الرياضة واللياقة البدنية (SFIA) أن مشاركة كرة المخلل في الولايات المتحدة قفزت من 13.6 مليون في عام 2023 إلى 19.8 مليون في عام 2024، بزيادة قدرها 461 تيرابايت إلى 3 تيرابايت.

كيف تضمن JOOLA الجودة من خلال بروتوكول الاختبار المكون من 7 خطوات؟

أنت تفكر في التصنيع في الخارج، ولكنك قلق من فقدان السيطرة على الجودة. هذا قلق ذكي. دعنا نلقي نظرة على النظام الذي تستخدمه أفضل العلامات التجارية مثل JOOLA لحل هذه المشكلة.

تطبق JOOLA بروتوكولاً صارمًا لمراقبة الجودة (QC) من سبع مراحل على كل دفعة من المجاذيف بعد إنتاجها. وتتضمن هذه العملية فحوصات مفصلة للوزن والتوازن وحبيبات السطح وقوة حافة الحافة، مما يضمن أن المجاذيف المصنوعة في الصين تفي بالمواصفات الدقيقة التي حددتها فرق التصميم الألمانية والأمريكية.

عيناك في المصنع

إن الثقة في الشريك الخارجي هي أكبر عقبة أمام أي علامة تجارية. والمفتاح هو بناء نظام من الضوابط والتوازنات. تقوم JOOLA بذلك بشكل جيد للغاية. وكما يشرح مدير البحث والتطوير، يورج سيفرز، "تتيح لنا عمليات وضع ألياف الكربون في الخارج تركيز أموال البحث والتطوير على تكنولوجيا السطح مثل الكربون المشحون بدلاً من النفقات العامة. لا تزال كل دفعة تخضع لمراقبة الجودة على سبع مراحل - بما في ذلك اختبارات سحب التصاق الحواف - قبل شحنها."

استناداً إلى خبرتي في إعداد هذه الأنظمة للعملاء، يبدو البروتوكول القوي المكون من 7 خطوات على النحو التالي:

- الفحص البصري: التحقق من وجود أي عيوب تجميلية أو عيوب في الطلاء أو مشاكل في المحاذاة.

- فحص الوزن والتوازن: التأكد من أن كل مجداف يقع ضمن حدود الوزن ونقطة التوازن الضيقة.

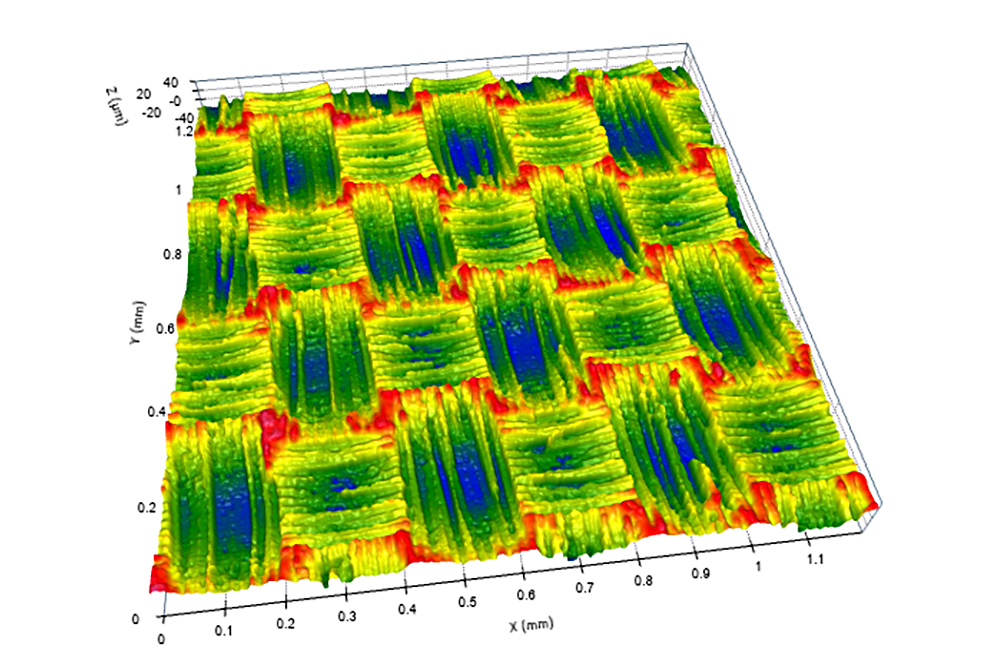

- اختبار خشونة السطح: استخدام مقياس تحديد الملامح للتأكد من أن مستوى الحبيبات متوافق مع USAPA.

- اختبار الانحراف الأساسي: قياس "البوب" للتأكد من أنه يفي بمعايير الأداء.

- اختبار التصاق واقي الحواف: اختبار سحب للتأكد من أن واقي الحافة ملتصق بإحكام ولن يتقشر.

- فحص المقبض والقبضة: التحقق من بنية المقبض وغطاء المقبض وغطاء الطرف للتأكد من الجودة.

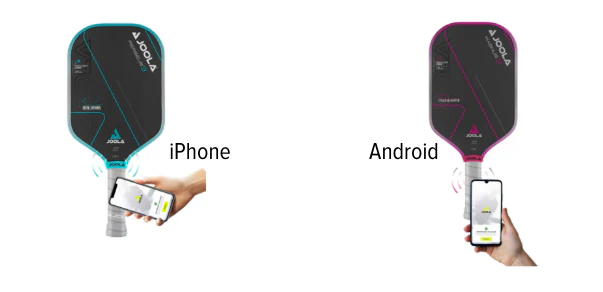

- التحقق من المصادقة: التحقق من صحة الرقم التسلسلي وتضمين شريحة NFC8 (كما هو الحال في سلسلة Pro IV & 3S) للأصالة.

هذه الخطوة الأخيرة حاسمة. للتحقق من وجود مضرب JOOLA حقيقي، يمكنك الآن استخدام هاتفك لمسح شريحة NFC الموجودة في المقبض وتسجيل الرقم التسلسلي عبر الإنترنت. وهذا لا يحارب التزوير فحسب، بل يمنح العملاء ثقة كبيرة في المنتج. هذا هو مستوى التفاصيل المطلوب للنجاح في التصنيع العالمي.

تتم إدارة عملية مراقبة الجودة في JOOLA بالكامل من مقرها الرئيسي في ألمانيا.خطأ

بينما يتم وضع المعايير في ألمانيا والولايات المتحدة، يتم تنفيذ بروتوكول مراقبة الجودة المكون من سبع خطوات على كل دفعة بعد الإنتاج في الصين، قبل شحن المجاذيف.

يمكنك التحقق من مضرب JOOLA الأصلي باستخدام شريحة NFC في المقبض.صحيح

تشتمل سلسلة JOOLA الأحدث المتطورة على شريحة NFC داخل المقبض تسمح للعملاء بمسحها ضوئيًا باستخدام الهاتف الذكي وتسجيل الرقم التسلسلي الفريد لتأكيد أصالتها.

الخاتمة

نموذج JOOLA للتصميم العالمي والتصنيع الصيني المتخصص ليس استثناءً، بل هو المعيار الجديد. إن فهم سلسلة التوريد هذه هو المفتاح لبناء علامة تجارية حديثة ناجحة في كرة المخلل.

المراجع

-

اكتشف كيف تعزز مصانع ألياف الكربون كفاءة الإنتاج وجودة المنتج في المعدات الرياضية. ↩

-

اكتشف أحدث الاتجاهات والابتكارات في إنتاج مجاذيف كرة المضرب. ↩

-

اكتشف فوائد ألياف الكربون في تعزيز الأداء والمتانة في المعدات الرياضية. ↩

-

تعرّف على تعقيدات ومزايا سلسلة التوريد العالمية في التصنيع الحديث. ↩

-

تعرّف على المعايير واللوائح التي تحكم جودة معدات كرة المضرب. ↩

-

فهم أهمية مراقبة الجودة والطرق المستخدمة لضمان تميز المنتج. ↩

-

اكتشف كيف يقود البحث والتطوير الابتكار والجودة في التصنيع. ↩

-

تعرّف على كيفية استخدام تقنية NFC للتحقق من المنتجات ومكافحة التزوير. ↩