Debe responder con confianza a las preguntas de los clientes sobre el origen de las palas. Pero la "Fabricado en China1" en una marca premium como Gearbox puede confundir y perjudicar las ventas.

La respuesta corta es que las palas de pickleball Gearbox son Diseñado en California2 y fabricados en China. Esto se indica claramente en las páginas de productos oficiales de Gearbox para modelos como la serie GBX y se confirma en los sitios web de los principales minoristas.

Este modelo "Engineered in the USA, Made in China" es muy común en el mundo del equipamiento deportivo de alto rendimiento. Como alguien que ha construido un negocio en torno a la fabricación de palas de pádel, he visto esta estrategia de primera mano. Es la forma en que las marcas acceden a tecnología de primer nivel al tiempo que escalan para satisfacer la demanda. Analicemos lo que esto significa realmente para usted y sus clientes.

Todas las palas Gearbox se fabrican en California.Falso

Las palas de cambio se diseñan en California, pero la fabricación se lleva a cabo en China, como se indica en sus páginas de producto.

Entonces, ¿las palas de cambio se fabrican en EE.UU. o en China?

Hay información contradictoria en Internet y se oyen cosas distintas en la cancha. Por eso es difícil dar una respuesta clara. Te arriesgas a parecer desinformado o a engañar a tus clientes.

Las palas de la caja de cambios utilizan un modelo de producción dividido: el diseño y la ingeniería se realizan en California, mientras que la fabricación física se lleva a cabo en China. Esto no es un secreto; la empresa es transparente al respecto en sus páginas de producto.

En mis años de trabajo con fábricas de paletas, este es un enfoque inteligente y estándar para las marcas de primera calidad. Permite a una empresa concentrar a su equipo estadounidense en lo que mejor sabe hacer -innovación y diseño-, aprovechando al mismo tiempo la especialización de sus empleados. Experiencia en fabricación3 en el extranjero. Veamos las distintas partes de este proceso.

La parte "Fabricado en California

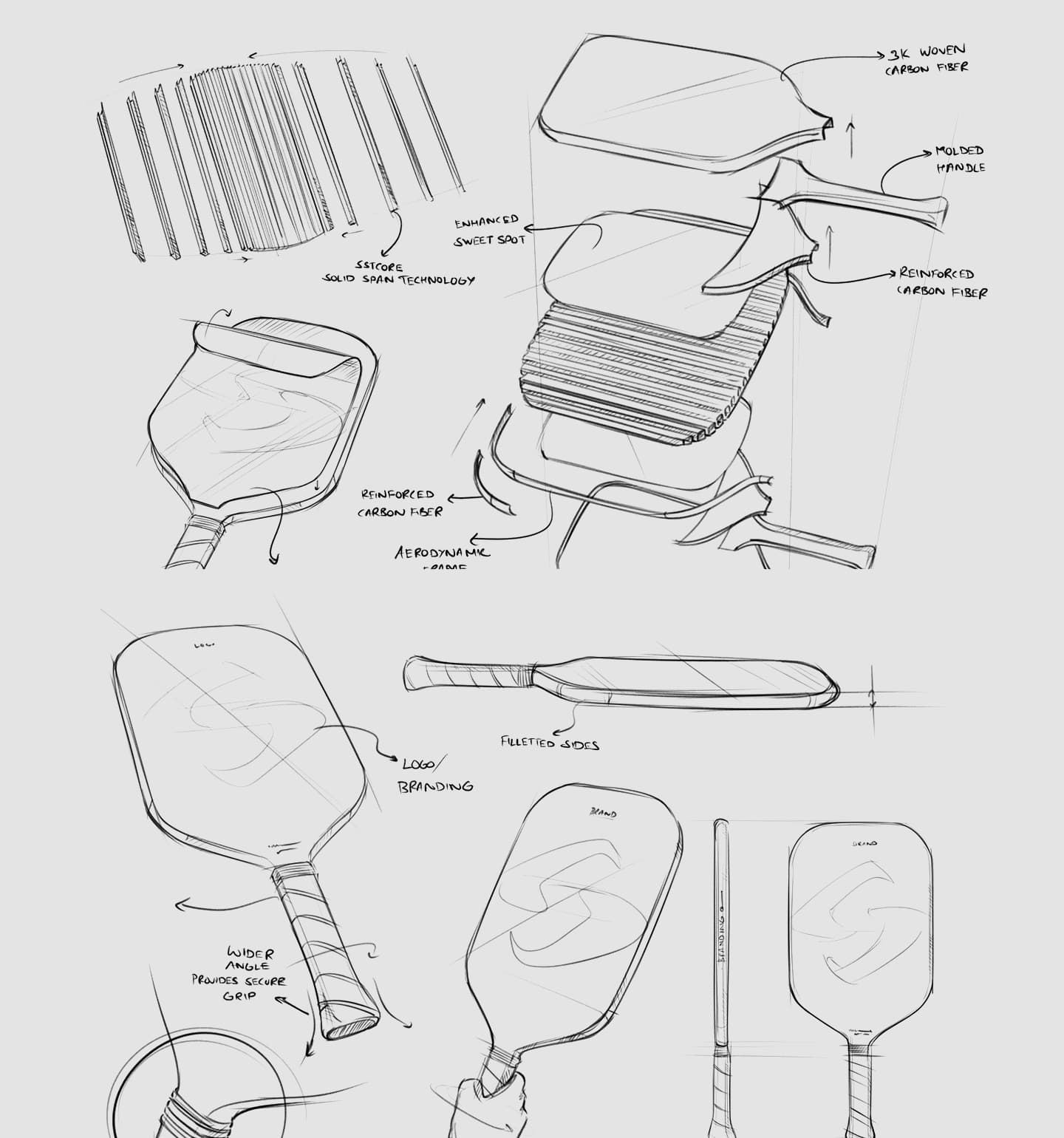

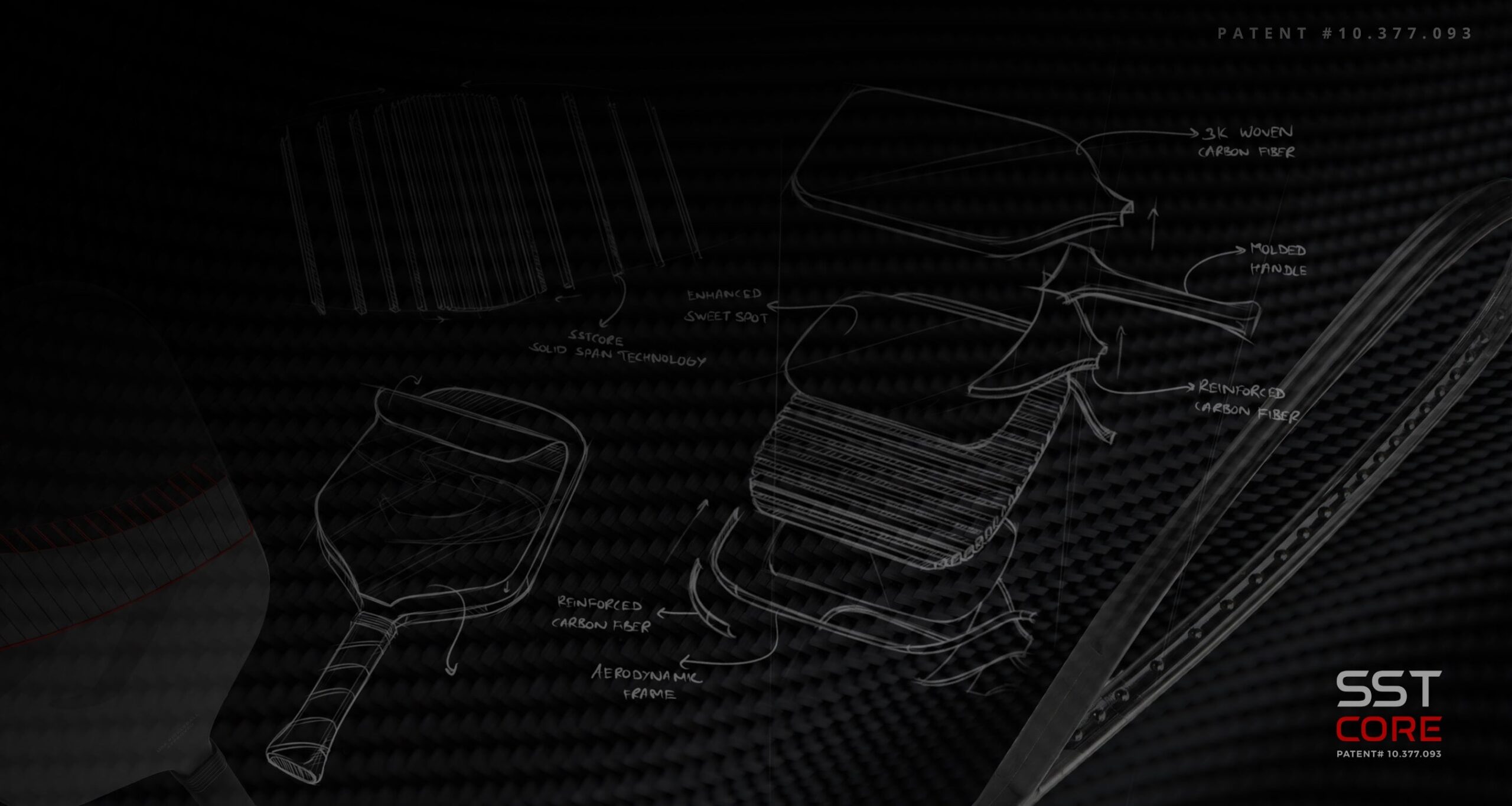

Este es el corazón del rendimiento de una pala Gearbox. El equipo de California es responsable del núcleo de la propiedad intelectual (PI). Esto incluye:

- Investigación y Desarrollo (I+D): Crear y probar nuevas tecnologías como la firma de Gearbox Tecnología Solid Span4 (SST). De ahí proviene el tacto único de sus palas.

- Diseño y especificación de materiales: Deciden la forma de la pala, el peso, el equilibrio y, sobre todo, los materiales exactos que se utilizarán, como los grados específicos de fibra de carbono.

- Prototipos y pruebas: Antes de que una pala pase a la producción en serie, se realizan prototipos y pruebas exhaustivas en EE.UU. para garantizar que cumple las normas de rendimiento.

La parte "Made in China

Una vez perfeccionado el plano en California, se envía a una fábrica especializada de China para su producción en serie. Por mi experiencia, no se trata de talleres de baja tecnología. Las mejores fábricas tienen una tecnología increíble para:

- Composites de precisión: Ensamblar capas de fibra de carbono es un trabajo altamente cualificado. Estas fábricas tienen el equipo y la mano de obra capacitada para hacerlo de forma consistente.

- Termoformado y moldeo: Crear palas unibody sin bordes requiere técnicas de moldeado avanzadas que muchas de estas instalaciones han perfeccionado.

- Control de calidad5 a escala: Pueden producir miles de palas y comprobar cada una de ellas para asegurarse de que coincide con el diseño original de California.

La parte "Barcos de Texas

Por último, las palas acabadas se envían desde China a Gearbox Centro de distribución en Texas6. Este centro con sede en EE.UU. gestiona toda la logística, incluido el envío de pedidos a minoristas como usted y directamente a los clientes. También es el centro de gestión de devoluciones y reclamaciones de garantía, lo que ofrece a los clientes un punto de contacto fiable en Estados Unidos.

La tecnología SSTCore de Gearbox se desarrolló en Estados Unidos.Verdadero

La ingeniería, la investigación y el desarrollo de las principales tecnologías de Gearbox se llevan a cabo en su sede estadounidense de California.

No es obligatorio que el país de origen de una paleta figure en la etiqueta.Falso

En Estados Unidos, la Comisión Federal de Comercio (FTC) exige que los productos importados lleven marcado su país de origen.

¿Qué significa "Engineered in California, Made in China" en términos de calidad y rendimiento?

Su cliente ve una etiqueta con un precio superior a $200 junto a una etiqueta "Made in China" y se muestra escéptico. Tienes que explicarle por qué merece la pena invertir en la pala, pero la etiqueta de origen dificulta la venta.

Este modelo significa que Gearbox combina la innovación estadounidense con la infraestructura de fabricación de categoría mundial de Asia. La calidad no viene determinada por el país, sino por el estricto control de la marca sobre el diseño, los materiales (como Fibra de carbono Toray T7007) y los procesos de garantía de calidad.

Cuando ayudo a las marcas a montar sus líneas de producción, nos centramos en el proceso, no en la ubicación. Un gran diseño puede arruinarse por una mala fábrica, y una gran fábrica no puede arreglar un mal diseño. El modelo de Gearbox garantiza la solidez de ambas partes.

La calidad está en el proceso, no en el lugar

La calidad de una pala Gearbox se cuece mucho antes de que llegue a la fábrica. La marca proporciona al fabricante chino un "tech pack", un detallado conjunto de instrucciones que lo cubren todo:

- Especificaciones del material: El tipo y grado exactos de fibra de carbono (por ejemplo, Toray T700).

- Layup Schedule: La orientación precisa de cada hoja de fibra de carbono.

- Parámetros de moldeo: La temperatura y la presión exactas para el curado de la paleta.

- Puntos de control de calidad: Una lista de inspecciones que deben superarse durante y después de la producción.

El trabajo de la fábrica consiste en ejecutar este plan a la perfección. Las mejores fábricas, como con las que yo colaboro, tienen certificaciones y un historial demostrado de hacerlo para grandes marcas mundiales.

El rendimiento depende de los materiales y el diseño

El rendimiento de una pala en la pista se debe a su construcción, no a su lugar de montaje. Los factores clave incluyen:

- Tecnología de base: El SSTCore sin bordes de Gearbox es fundamentalmente diferente del panal de polipropileno de la mayoría de las palas. Este diseño es el principal impulsor de su sensación única y durabilidad.

- Material de la cara: El uso de un material de alta calidad como la fibra de carbono Toray T700, que es un estándar mundial en el sector aeroespacial y los deportes de alto rendimiento, garantiza una superficie sensible y duradera.

- Aprobación USAP: En Aprobación de USA Pickleball8 no tiene en cuenta el país de origen. Sólo comprueba el cumplimiento de las normas de rendimiento (rugosidad de la superficie, deflexión, etc.). El hecho de que las palas Gearbox estén homologadas por la USAP demuestra que cumplen las normas de rendimiento más exigentes de este deporte.

La homologación de USA Pickleball depende del lugar de fabricación de la pala.Falso

La homologación USAP se basa en pruebas de rendimiento y en el cumplimiento de las especificaciones técnicas, independientemente del país de origen.

Toray T700 es una fibra de carbono de primera calidad que suele utilizarse en palas de gama alta.Verdadero

Toray T700 es una conocida fibra de carbono de alta resistencia a la tracción de un fabricante japonés, utilizada en todo el mundo en productos compuestos de primera calidad.

¿Cómo puede verificar el origen de la paleta de su caja de cambios?

Quiere ofrecer información precisa, pero no está seguro de dónde encontrar la información oficial. Confiar en publicaciones de foros o reseñas obsoletas es arriesgado para la credibilidad de tu empresa.

Para verificar el origen de una pala, consulte siempre primero las fuentes oficiales. La página del producto en el sitio web de la marca es el lugar más fiable, seguido de las especificaciones técnicas en los sitios de los principales minoristas y la etiqueta física del producto.

Como empresario, la verificación es clave. Siempre les digo a mis clientes que creen un archivo para cada línea de productos con capturas de pantalla y enlaces. Aquí tienes un proceso sencillo que puedes seguir para cualquier marca, utilizando Gearbox como ejemplo.

Paso 1: Consulte la página oficial del producto

Ve directamente a la fuente: El sitio web de Gearbox. Navega a una paleta específica, como la Modelo GBX 8oz. Si se desplaza por la página, encontrará el texto "Diseñado en California - Fabricado en China" claramente en la lista. Es la confirmación más directa que puede obtener.

Paso 2: Mira las especificaciones de los principales minoristas

Los grandes minoristas de renombre como Pickleball Central hacen su propia diligencia debida. En su página de producto para el Caja de cambios Pro Ultimate Power 14 mmsi hace clic en la pestaña "Especificaciones", verá una línea "País de origen" que dice explícitamente "Made in China". Esto proporciona una excelente validación por parte de terceros.

Paso 3: Examinar el producto físico y el embalaje

Las leyes de importación de EE.UU. exigen que los productos lleven marcado su país de origen. Cuando reciba su inventario, compruebe la propia pala. La información suele estar impresa en la garganta de la pala, en la tapa de la culata o en una pegatina en la envoltura del mango. También estará en la caja o embalaje original.

Paso 4: Revisar la garantía y la información de la empresa

Las páginas "Quiénes somos" y "Garantía" del sitio web de una marca también pueden dar pistas. En ellas se indican las direcciones en EE.UU. de la sede central y la distribución, lo que aclara las funciones de cada ubicación. El proceso de garantía de Gearbox se gestiona a través de sus operaciones en EE.UU., lo que refuerza la ubicación de sus servicios de cara al cliente.

Los sitios web de minoristas como Pickleball Central indican el país de origen de las palas.Verdadero

Los grandes minoristas suelen incluir el "país de origen" en las tablas de especificaciones de sus productos, lo que constituye una fuente de información verificable.

Parece extraño que las palas más innovadoras y caras no se fabriquen en EE UU. Esto hace difícil justificar un precio superior cuando los clientes asocian la producción en el extranjero con el bajo coste.

Muchas marcas de pickleball de primer nivel fabrican en Asia para aprovechar la gran experiencia y la enorme infraestructura de la región en la fabricación de compuestos de fibra de carbono. Esto permite técnicas de construcción avanzadas, escalabilidad y una consistencia de calidad difícil de igualar en otros lugares.

He pasado mucho tiempo en estas fábricas, y la idea de que son instalaciones de "mano de obra barata" está desfasada desde hace décadas. La realidad es que, para determinados tipos de fabricación, son las mejores del mundo.

Un centro mundial de expertos en materiales compuestos

Durante décadas, países como China y Taiwán han sido la columna vertebral de la industria de artículos deportivos de alto rendimiento. Fabrican las mejores raquetas de tenis, cuadros de bicicleta y palos de golf del mundo. Ahora, esa experiencia se está aplicando al pickleball. Lo han hecho:

- La tecnología: Maquinaria avanzada para termoformado, moldeo CNC y aplicación robotizada de texturas.

- La mano de obra cualificada: Un gran equipo de técnicos especializados en el delicado proceso de colocación manual de la fibra de carbono.

- La cadena de suministro: Fácil acceso a los proveedores de materias primas y una red logística construida para la exportación mundial.

La instantánea del mercado: Historia de dos modelos

Este modelo de producción globalizada es ahora el estándar de la industria para la mayoría de los remos de fibra de carbono. Aunque algunas grandes marcas siguen fabricando en EE.UU. (a menudo utilizando materiales o procesos diferentes), el panorama está dominado por la estrategia "Diseñado en EE.UU., fabricado en Asia".

Aquí tienes un breve resumen:

| Marca | Modelo(s) de ejemplo | Origen declarado | ¿Aprobado por la USAP? | Garantía |

|---|---|---|---|---|

| Caja de cambios | GBX, Serie Pro | Diseñado en California, fabricado en China | Sí | 1 año |

| JOOLA | Perseo, Hiperión | Diseñado en Alemania, fabricado en China | Sí | 6 meses |

| Vatic Pro | Prisma, Flash | Diseñado en EE.UU., fabricado en China | Sí | De por vida |

| Visite | Pursuit, Encore | Fabricado en EE.UU. | Sí | 1 año |

Esta tabla muestra que el origen es sólo una pieza del puzzle. Para su empresa, es más importante centrarse en los factores que repercuten directamente en el cliente: rendimiento, garantía y respaldo de la marca.

La mayoría de las palas de pickleball de fibra de carbono de primera calidad se fabrican en China.Verdadero

La mayoría de las marcas líderes del mercado de palas de fibra de carbono termoformadas y en bruto utilizan instalaciones de fabricación en China.

Conclusión

Las palas de cambio se fabrican en China con ingeniería estadounidense. Este modelo de alto rendimiento es el estándar del sector. Céntrese en la tecnología, los materiales y la garantía de la pala para ofrecer el mejor servicio a sus clientes.

Referencias

-

Explorar las razones de la fabricación en el extranjero puede ayudar a justificar la calidad y el precio de las palas Gearbox. ↩

-

Comprender el proceso de ingeniería puede aclarar la calidad y la innovación que hay detrás de las palas Gearbox. ↩

-

Explorar las avanzadas capacidades de fabricación puede ayudar a los clientes a apreciar la calidad de las paletas Gearbox. ↩

-

Conocer el TSM puede aportar información sobre las características exclusivas que distinguen a las palas Gearbox. ↩

-

Comprender los procesos de garantía de calidad puede generar confianza en la marca Gearbox y sus productos. ↩

-

Conocer el proceso de distribución puede aclarar cómo gestiona Gearbox la logística y el servicio al cliente. ↩

-

Descubrir las ventajas de este material puede ayudar a los clientes a comprender su impacto en el rendimiento de las palas. ↩

-

Explorar el proceso de homologación puede ayudar a los clientes a sentirse seguros de los estándares de rendimiento de las palas Gearbox. ↩